News

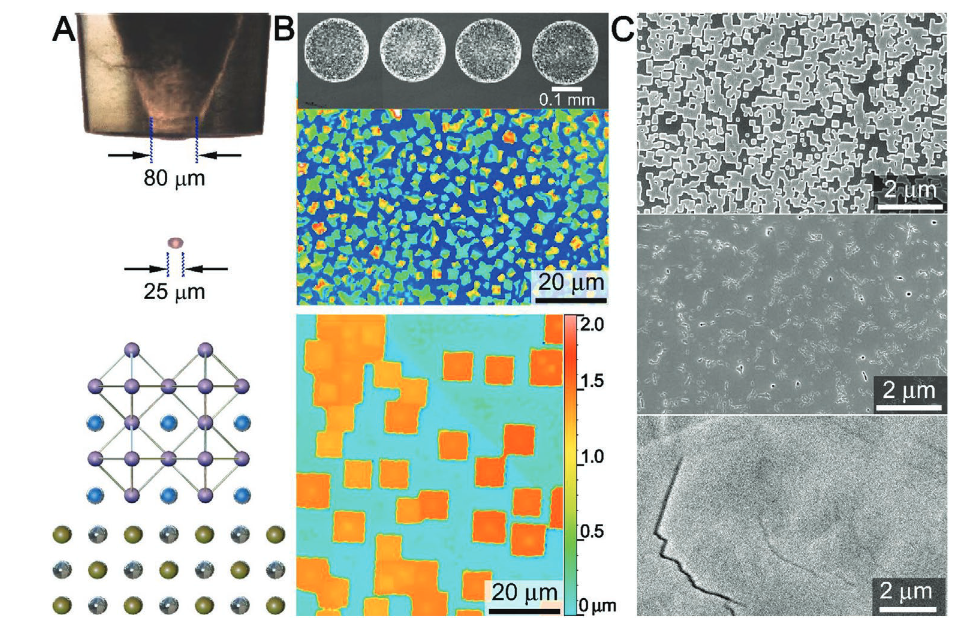

The role of substrate for inkjet printer CH3NH3PbBr3 perovskites. A) Ejection of a single droplet from a piezoelectric driven glass nozzle with an orifice of 80 μm (top). Schematic interface between CH3NH3PbBr3 perovskite and PbS having a cubic rock salt structure with a lattice mismatch ≈0.3% (violet = iodide, blue = CH3NH3, silver = lead, yellow = sulfur) (bottom). B) Printed structures on non-crystalline surfaces: glass (top), untreated GaAs (middle). Confocal optical microscope images of printed CH3NH3PbBr3 microcubes exhibiting an epitaxial relation to the PbS substrate (bottom). C) Scanning electron microscope images, exhibiting samples with increasing amount of deposited material showing an evolution from cubic crystallites merged to islands, to closed film. The full film at (C-bottom) and the big crystallites in (B-bottom) were obtained at a humidity of 80%, whereas the structures in (b-middle, c-top and middle) were printed at 40% humidity.

The paper was co-authored by V. Volobuev, J. Korczak and T. Story from MagTop. The authors show that the inkjet-printing of metal-halide perovskites provides improved material characteristics in a highly economical way, as a future cheap competitor to the high-end semiconductor growth technologies.